3D Printer Hints and Suggestions

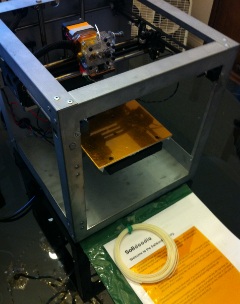

Looking for some 3D Printer Hints? You have come to the right place. I've been working with my 3D printer for over a year, well, I've owned it a bit over a year, I've only been running it a few weeks. Why? See my Solidoodle Printer review.

In those short weeks, I've hit several issues that I have since (with the help of a good friend) solved. I want to pass that info on to our readers. Some of it is just common sense and others is experience.

After doing 3D printing I found a lot of seemingly difficult issues that actually had simple answers. Things such as the correct print temperature drove me crazy. Below are my 3D Printer Hints, tips and gotchas for your benefit.

I will be adding more as time goes on. If you have a good suggestion, send it to me and we will probably add it to this page.

--Thomas

BEFORE You Print :

3D Printer Hints

To ensure that your print gets off to a good start, a few minutes of preparation and checks is a very worthwhile investment of your time.

1. Wipe down your bed WHILE IT IS COOL with acetone. This removes any dust contaminants or oils from the bed. Acetone is VERY FLAMMABLE! NO SMOKING! NO FLAMES, OR ANY KIND OF FIRE SHOULD BE IN THE ROOM.

2. Ensure that the bed temperature is up to the right number. For me and my Solidoodle, (ABS plastic) that is 100 C.

3. Ensure that the hotend/ heater is up to its right temperature too.

4. Extrude a mm or two of plastic to ensure that your nozzle is primed and full of fresh molten plastic.

5. Remove ALL plastic drips from the hotend tip. Bits of hardened plastic sometimes will unstick your print from the bed and that is never good.

3D Printer Hints : Need a review of theSolidoodle Printer? Click HERE!

More 3D Printer Hints:

Run a couple of mm of plastic through the hotend before starting a new print to ensure that it is full, primed, and ready to start. You would not believe how many times I've had to restart a print job just because all the hot goopy plastic had dripped out just before starting the print job.

A long thin needle nose works great for removing that extra plastic that drips and hardens. I've tried using my fingers. I got burnt. BAD IDEA: Fingers on a hot machine!

Label your parts as you print if you are printing a multi-piece thing. I have several parts that look like several other parts that I am not sure that I printed because I didn't label my parts.

Lower your bed temp to about 185 (ABS) to remove your part.

Blowing a fan on the print bed helps lower the temperature quickly!

More 3D Printer Hints:

Don't leave your hotend on if you need to leave. It burns the plastic and causes clogs.

In spite of what Solidoodle told me about clogged printer heads being a rare event, I found that ALL printers will clog. Some more than others. The Solidoodle clogs about once ever 2-3 hours. Get used to it and get used to cleaning out the hotend. A thin guitar string works well.

Using tweezers or a thin pair of pliers, tug at the strand dropping from the hot end. It should be a bit gooey before printing.

Watch carefully the raft, and then first layer as it prints. If a part is going to go bad, the first few minutes is where it will happen.

Set extruder temperature at a temperature hot enough to melt the plastic and make it somewhat gooey, but not hot enough to burn it nor burn out your print head.

More 3D Printer Hints:

Extrude a few mm of plastic before printing to ensure your extruder is primed and ready to start.

Quickly and carefully pull off any plastic strands off the print nozzle before printing.WATCH YOUR HANDS and FINGERS, it's HOT!

Again, if you have a printing tip to share, Send it to me. If it is a GREAT ONE I will add it to this page.

and

If you have a 3D printing problem that you would like us to help you solve, send that as well.

--Thomas

3D Printers Hints : Problems and Solutions

The 3D Printer Hints listed below assume that you are using:

- Printer Software: Printerface / Printer Interface

- Slicing Software: Skeinforge

- A Heated Bed

<----------------------------------------------------------------------------------------------------->

Problem: How do I print without a raft?

Solution: There is a checkbox in Skeinforge that can be unchecked and this will

allow printing without a raft. You need to do this before you slice up your drawing.

Problem: My print does not stick to the print bed.

Solution: For ABS plastic you MUST have a heated bed . If you have a heated bed, try turning the temperature up some. The suggested temperature for ABS is 100 degrees C.

If you do not have a heated bed, you must use PLA. Then just use painter's blue masking tape on the bed to get it to stick.

Problem: The temperature is changing on the hotend while printing.

Solution: This drove me fricken crazy for weeks. It seems that Skeinforge allows the user to set the print temperture inside of the g-code and does so by default. Your g-code probably has instructions telling the printer to change the temperature of the hotend. If you look in the g-code for the letter "M" and the letter "S". "M104" is tells the printer to change the temperature and "S" is the temperature it is to be changed to.

M104 S190.0 = set the hotend to 190 degrees C.

You can manually edit your g-code temperature instructions or re-slice your model setting the g-code at the proper temperature in Skeinforge.

More 3D Printer Hints:

Problem: My print is hard to remove from the printer bed.

Solution: Let the print bed cool off to about 75 degrees C before attempting to

remove it. i I use a small fan to cool it more quickly.

Problem: My printer head is clogged.

Solution: Make sure it is really clogged. Different plastics require different temperatures. First try raising the temperature a degree or so to make sure. If it was working and then stopped producing plastic out it's CLOGGED (happens quite often, even with Solidoodle), you need to take out the plastic feeding into it, and with the printer temperaturre up to its required temperature, carefully force a wire SMALLER THAN YOUR EXTRUDER'S HOLE into it. For my printer, I needed to use a steel guitar string. This was VERY HARD TO DO AND I BURNT MYSELF SEVERAL TIMES ON THE HOTEND!

Problem: The plastic comes out way too slowly on my hotend.

You might have one or more of these problems:

Solution 1: Too much plastic dust in the plastic feeder, so cleand the dust from the feeder gears.

Solution 2: Raise the hotend temperature. Different plastics require different temperatures. I've seen ABS plastic that would not get sufficiently molten until the hotend hit 210 degrees. Try raising the temperature a bit. BUT BE CAREFUL! IF IT IS TOO HOT, THE PLASTIC WILL BUBBLE AND POSSIBLY BURN AND CARBONIZE CREATING A BAD CLOG IN THE HOTEND! Also, some hotends are DAMAGED if the heat is too high.

More 3D Printer Hints:

Problem: The plastic comes out too stiff and does not stick to the bed nor other layers of the print.

Solution: Again, you probably don't have the hotend hot enough for the plastic that you are using. Raise the hotend temperature. Different plastics require different temperatures. I've seen ABS plastic that would not get sufficiently molten until the hotend hit 210 degrees. Try raising the temperature a bit. BUT BE CAREFUL! IF IT IS TOO HOT, THE PLASTIC WILL BUBBLE AND POSSIBLY BURN AND CARBONIZE CREATING A BAD CLOG IN THE HOTEND! Also, some hotends are DAMAGED if the heat is too high.

Problem: My prints come out with obvious ridges and strands of plastic hanging off of it.

Solution 1: Get used to it. Except for the very high end, very expensive 3D printers (about $50,000 and up), 3D printers for the home and hobby market seldom make smooth prints.

Solution 2: One solution is to sand your print to smooth a bit. Use an extra-fine sand grit.

Solution 3: Another solutions for ABS plastic is to paint a thin coat of acetone (sometimes found in nail polish remover) on your print. BE CAREFUL: ACETONE IS VERY FLAMABLE! Some people actually give their prints a quick dip in an acetone bath. I've never tried the dip. Be careful with acetone. Besides being flamable, it will soften a print and if to much is used, it will begin to dissolve a print. It also makes the plastic sticky until it evaporates.

Solution 4: I like to trim the larger plastic strands off with electrician's diagonal cutters (the slender ones you find at Radio Shack meant for thin-guage wire), then do a bit of sanding and finally apply a thin coat of acetone to my print. The acetone makes it shiny!

More 3D Printer Hints:

Problem: My print has bubbles in it.

Solution 1: Your hotend is TOO hot. Turn it down a degree or so.

Solution 2: You have condensation on your plastic filiment stock. Dry it off by blowing on it with a no-too-hot hair dryer. DO NOT USE AN ELECTRICIAN'S HEAT GUN!

Problem: I'm not sure how hot does my hotend need to be.

Solution: The rule of thumb is 200 degrees C for ABS plastic and 185 degrees C for PLA plastic. Now there are some plastics that need higher temperatures and a few that need lower temperatures.

The trick is to have it hot enough so that a tiny bit of plastic drips from the hotend while it is sitting idle, but not so hot as to make it bubble.

Got any 3D Printer Hints? Pass them on to us!

--Thomas