Solidoodle Review

UPDATE: We have

FIXED

our Solidoodle Printer!!!

UPDATE: 6-18-13

I've discovered an error or at least a contradiction in Solidoodle's online instructions.

On one section they stated that users will have a problem with plastic dust if the heater is set below 210C.

"The deep teeth of the drive gear are designed to accommodate some amount of shredded plastic but may clog if the plastic accumulates. This can happen if the extruder motor is run while the heater is below 210C, which can cause the drive gear to strip the filament. In this case, filament may squirt out of the nozzle intermittently, as the drive gear alternately grabs and slips against the filament. "

While on another web page they stated,

"Please be advised that if you print over 200C you run the risk of damaging the hot end."

Which is right? I really do not know. I do know that if you print at a temperature that does not melt your plastic sufficiently, your print will come out bad if at all. Different plastics even from the same vendor will have different melting points. My plastic NEEDS 210C or it barely comes out of the hotend and I get awful prints. And if set at 210C, it will fluxuate by a couple degrees above and below the set temperature. Has my hot end been damaged? I don't think so. I'm still printing parts.

UPDATE: They have changed their help pages.

I wish Solidoodle would get their act together.

UPDATE: 5-25-13

I'm PRINTING THE INMOOV ROBOT on my SOLIDOODLE!

and

IT HAS YET ANOTHER PROBLEM!!!

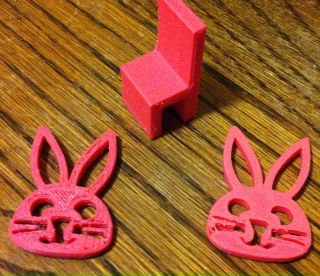

So, the printer has been up and running for about a week and in that time I have printed several tiny toys for miy daughter and I have begun printing the InMoov robot. I am starting with the hands and already they have been printing nearly non-stop for several days now.

That is the good news! Here is the bad: I am unable to center my Z axis from Pronterface unless I manually bring it up a few centimeters at a time. If I hit the Z-center button, the Z axis motor seizes up and makes a most HORRIBLE sound! I then need to reset that bad boy to get it to work again. I don't know why it is doing that. My friend thought it just needed some grease, so I greased it. That did not help the issue. Again, I can print but I need to raise the bed manual until it is just a few mm from the print head. It's a pain, but still, I'M PRINTING!!!!!

I've begun looking for another 3D printer to buy. I am looking into all the ones that are under $600 and are fully assembled. There are not many that fit that bill. You might call me crazy, but I might buy another Solidoodle. I'll make that decision after my InMoov robot is printed!

UPDATE: 5-19-13

I'm not selling my3D printer just yet.

A friend dropped by who knows a lot about 3D printers. He is working for AirWolf 3D and owns one of their printers as well. He took a good look at my Solidoodle 3D printer and told me a probably scenario of why my printer got all messed up:

1. It looks like the print bed had NOT been leveled before shipping.

2. It also looks like the print bed Z-axis adjustment screw was set wrong before shipping. More about that later.

2. This caused a print head crash into the bed.

3. This broke the clear plastic piece in the extruder head.

4. Also, it caused the threads on the plastic Z-limit switch adjustment block to strip its threads.

5. With the head touching the bed, the molten plastic could not flow out.

6. Eventually the plastic, which became stuck inside the printer head for a few hours, turned to black carbon preventing any more plastic to flow.

7. The carbonized plastic then acted like a glue causing the extruder tip to permanently bind itself to the extruder shaft, thus not allowing the tip to be removed without damage to the extruder shaft.

8. Another problem was that the Z-axis adjustment screw was at its maximum setting, upon arrival to me and still the bed was too low.

So, since the plastic Z-limit switch adjustment block was stripped, we needed a new one.

1. We tried adding some molten white plastic to the part to fix the threads.

2. That did not work so my friend took my original to his house and designed a new one using 3D cad software.

3. Next he printed a new on on his AIRWOLF 3D PRINTER! (In the photo, the original printer Z-axis adjustment block is the BLACK one with the white goo. The new one we printed on an AirWolf 3D printer is in BLUE.)

4. He drilled holes for it.

5. Tapped the center.

6. Mounted it back in place of the old one.

Now, the original screw was too short to adjust the bed's z-hight. The solution was to either 1. Re-drill the holes on the printer wall that were used to attach the adjustment screw block, or 2. use a longer screw. We decided to use a longer screw.

7. So we put a longer screw (1.25") in place of the original.

8. Leveled the bed.

9. Adjusted the bed z-limit. The longer screw allowed this.

10. And finally tried a sample print.

IT WORKED! My printer is printing again!!!!! YAHOOOOOOO!!!!!!!

I will not be selling it just yet. I will try printing for a week or two and then make my decision.

-

You know, all new technologies have their problems and 3D printing is no exception. The only real complaint I have is HORRIBLE CUSTOMER SUPPORT IN SOLVING MY MULTIPLE ISSUES.

So, perhaps the newest Solidoodle 3D printer (version 3) may be better than mine (version 2), but still I will not be buying one. There is one thing that has not changed since I bought it more than a year ago: Solidoodle CUSTOMER SUPPORT IS AWFUL. And that's enough reason for me to say DON'T BUY A SOLIDOODLE.

On a related note, I suggested to my friend that he start a business fixing Solidoodle 3D printers. He said that he would not have too many customers. Do me a favor. If you have a broken 3D printer that needs fixing, PLEASE leave a comment so that I can show him there is a need for a 3D fix-it shop!

--Thomas

3-3-13 UPDATE:

They said they would replace our machine, but have changed their tune and will not be replacing our broken unit. Sigh. I just want to print stuff!

The lemon of a printer that we were sold back in May of 2012 will NOT YET go up for auction on eBay.

Starting bid for that lame, uh rather WONDERFUL bit of machinery MIGHT BE : $1.

Actually, it does work--kind of. The bed needs to be constantly adjusted. I think the z axis was never set right. And there are several cracks in the extruder/hot end support piece. I hope the Solidoodle III (Solidoodle 3) printer is more robust than the Solidoodle II.

We were told just today by a Solidoodle rep that there is no warranty on ANY Solidoodle printer (we knew that) and it came from "high up" that there will be no exchange for our broken 3D printer even though it only gave us less than a week of service in over 9 months. It isn't fun flushing $600 down the proverbial toilet. Sigh. Flush. Cry.

We are hoping that a 3D printer-savvy person, perhaps a Solidoodle repair tech, will buy it and give it the tender, loving care that it surely needs to get it going again. See below for the whole story.

Check back and we will be posting which day it will go up for auction!

Solidoodle Review

Unless things change, we suggest that it is best to save your money for a more expensive printer.

This author bought the inexpensive Solidoodle 3D printer. Within 3 days, it lay broken with a jammed/broken printer head. After four hours of attempting to clear the jam, the printer is now sitting idle waiting for a support person from Solidoodle to find out what to do next to resolve the problem. The full story is below.

NOTE: Solidoodle DOES NOT offer any kind of warranty. They may add one someday, but on their site it plainly states that they will do their best to help with problems, but there is no warranty.

For the longest time I've wanted to get a 3D printer. You see, there is this robot hand, wrist, and arm that I wanted to print out and being that usable robot arms tend to cost in the tens of thousands of dollars, I figured if I bought a 3D printer, I would be ahead of the game and be able to print, assemble and sell them to others.

I've been reviewing printers for some time now and at $1200 and up for a 3D printer, I was waiting for a sale, or at least a printer with enough features to justify that cost. Besides, I was saving my money for a new car and that would take a sizable chunk from my down payment. I searched for a Solidoodle review, but none were to be found.

And then while looking at some side-by-side comparisons of product, price, performance, and print envelope, I saw the Solidoodle for $499. And it was already in its second stage: Solidoodle 2! It was pre-assembledl, came with software, and per their own site, one would just load software, grab a 3D model and PRINT PRINT PRINT!

Solidoodle Review: Solidoodle's Own Web Site

I looked online for someone who had bough the printer and had posted a Solidoodle review. No such luck.

So, I went to their page, saw that one needed to pay an additional $50 for a heated bed (seems like this should be standard) in order for the 3D models to stick right, and ordered one. I paid for my 3D printer with PayPal and smiled knowing that in a short 2-3 weeks my printer would arrive.

(Note: I later regretted not getting the official $50 3D printer cover that would protect me from the nasty and very painful 2nd degree burn which I got on my finger the first day of printing. Where was that Solidoodle review when I needed it?)

So, four weeks came and went and no printer arrived. I wrote to Solidoodle asking if my order could be expedited since I wanted to review the printer for this web site. The answer was a resounding "NO WAY!" OK, I thought, I'm just another customer, so I waited another two weeks. Still no printer arrived. I wrote to the company. They wrote back and said they had gotten so many orders that they were backed up and it would be at least three weeks until my order arrived. Well, the 3D printer arrived a FULL 4 MONTHS LATER!!!!! (I started seeing Solidoodle reviews, not on the product, but on the amount of time people were waiting to get their printers.)

Well, I thought, things happen and I just took it in stride and unpacked my BRAND NEW 3D PRINTER. It unpacked fairly simply. It was well packed, but not overpacked. All things were there. Nothing was broken. I was happy!

I went to their web site for the manual. (It seems that absolutely NO ONE is packing manuals inside of products anymore.) I started downloading the required open source software and drivers for my PC. It was straight forward and I had the software and drivers in place in just under an hour. I was quite excited at that point!

I went to Thingiverse, and as per instructions, downloaded a small 3D model, a cat for my first print. I ran it through Skeinforge, an opensource application that takes a 3D model and slices it up into printable layers. It can take several minutes for even a small model to run through Skeinforge.

I then launched and spent about 20 minutes trying to connect the printing software called "Pronterface" (or "Printer Interface" if you are looking at the name in the app's window) to the printer itself. Seems that I needed to try several of the USB ports the first time around to pick the right one.

Next I clicked the "Connect" button and waited, and waited, and waited. Nothing connected. I looked at the DOS window that was sitting in the background. A lot of funny characters were printed: AHHHH! the baud rate was wrong. Solidoodle requires 250000 baud, while the default was 125000. I changed the baud rate, clicked "connect" and it finally connected!

Next I saw that the printing software defaults were set, so I just accepted the defaults and pushed the Print button. Oops! Printing head was not hot. Safety device told me it could not extrude if the head was cold. OK. I looked at the GUI, ah! I needed to click "Set" to turn on the heater on the print head. "Hey, I'm an engineer! I'm a roboticist! I'm the president of this damn web site, I can DO THIS!"I exclaimed so loud that my black tabby cat jumped. AND it started printing. Black goopy plastic started spurting out of the print head and started building up what was quickly becoming a plastic cat! WOO HOO!!!!! IT WAS WORKING--until it got to be a bout 1.5" tall and then came loose from the print bed. OOOOOOPS!!! I looked at the temperature for the print bed. It was standing at a bit above room temperature. Sigh, it needed to be "Set" as well. I set it to 100 degrees C and waited about 15 minutes for it to heat up. Meanwhile I pulled off the now very distorted half-printed cat and tossed it into the trash. Sigh.

With the print head hot and the print bed hot, I once again pushed the print button and all over again it started printing. As it got around the cat's ears, my daughter, who was watch her daddy's as he overcame each frustrating issue, began to get excited! "Look Daddy, it's nearly DONE!" she exclamed nearly putting her finger onto the print bed. That's when I decided that I would see if I could buy a cover for the unit. One burned finger (mine) was one too many.

After what had been a bit over an hour the cat was finished. And my daughter took it, warm from my hands and ran across the house. She was happy! I was happy!

Now on to more pressing matters, printing a ROBOT HAND, WRIST, ARM, and ELBOW!!! I was guessing that at that point a Solidoodle review was not going to be needed and that I would be printing my own Solidoodle review.

I downloaded the 3D models for the hand, ran the top hand cover through Skeinforge and loaded it into Pronterface. I "Set" the both the print bed and print head temperatures as per Solidoodle's recommendations, 100 and 200 degrees respectively. I then pressed "Print". Four hours later the 3D model was finished! WOW! I was on my way to my first robotic hand!!!!

The Solidoodle Review!

The next night, I set up the "wide wrist" piece for printing. It was going to take about 5 hours or so, so I decided to let it print through the night. I pushed the "Print" button and went to bed. I came into my lab and looked at the piece. It seemed to be about half done. I was a bit confused. Had the computer shut down? Had the power gone off? Had the cat inadvertently cancelled the print with her paw?

I restarted the computer and restarted the printer and pushed that wonderful "print" button all over again. This time the printer head seemed to howl with a high pitched whine. I cancelled the print and looked around. At first I thought it was the motors, but when I backed out the print stock (the ABS plastic string), the noise stopped. I then put the stock back in place and clicked print again. The printer went through the motions and at first only a few drops of melted plastic came through the print head. After about 8 seconds the plastic stopped. The print head was still racing around the print bed, but it was printing nothing. I stopped the printer again and started to further examine the issue. I found nothing. I wrote an email to Solidoodle and the next day they replied. By this time I started writing this Solidoodle review.

The Solidoodle Review!

They said that this happens from time to time and that it was fixed with a pin or a paper clip. I then removed the back mono-filament from the print head and jammed a paper clip into it. No go. I then heated up the print head and proceeded to pull out a bit of hot black plastic from the printer head. I put the filament back in and pressed print. No go. I removed the filament and tried putting a pin up into the print head from the bottom. It did not fit. I tried a tiny sewing needle. It did not fit. I tried a guitar string. It went through the print head. I figured my jam was unjammed. That did not work either. Although a tiny bit of black plastic did come through when I started once again printing, it seemed that something big was inside blocking the flow of molten plastic. I was by that time SO VERY FRUSTRATED. More than four hours had passed since I had begun this session of troubleshooting. And, I burnt myself twice on the extruder head. You need to leave it at 200 C (392 F) while unclogging it so that the plastic can flow out.

9-29-12 Update: So now it is Saturday. I've got the Riverside Robot Expo coming in 5 weeks. (I wanted to show off a printed arm. Sigh. That's not going to happen.) And I have a broken Solidoodle printer just sitting there idle. Too bad. I had seriously considered (at this price who wouldn't) buying 3 or so more printers and going into the printing business. I surely wish someone else had published a Solidoodle review of the product. If I had read about what I had experienced, I would have chosen differently.

The Solidoodle Review!

9-30-12, Sunday Update: I left an email asking them to replace the print head. I was asked a second time what was wrong.

10-1-12, Monday Update: I wrote early Monday morning, again asking for a new print head, but by Monday night I had not heard anything from them. I also asked if I uploaded a video, would it help. No messages from Solidoodle support today.

10-2-12, Tuesday Update: I saw a video on youtube showing a man cleaning his print extruder head with a Burnzomatic torch. I wrote to support to see what they thought. I wrote a separate email asking how I should go about disassembling the print head. No messages from Solidoodle support today.

10-3-12, Wednesday update: I got a response back. Actually two responses.

1. They stated that printer jams are common. And that this, unclogging the print head, is part of owning a 3 dimensional printer and it requires patience. This is very different from their troubleshooting page that states "Clogged nozzles are exceedingly rare..."

The Solidoodle Review!

2. They also responded on my question about using a Burnszomatic torch to melt out the stuck plastic. I was told that it could DEFINITELY harm the printer. AND Support finally asked me if I had time for a Skype session. I told them I did have time on Friday. We shall see what happens!

Please understand, I only want to print cool stuff. I don't want my money back, I don't just want to complain, I want a working 3D printer to print out robot hands, robot arms and robot brackets. I had only run the machine for about 6 hours TOTAL before it jammed. Maybe I expect too much. Maybe they promised too much. Either way, I'm still waiting for a workable method to unclog my printer.

10/5/2012, Friday Update: Finally had some time to call Solidoodle, or rather Skype solidoodle. It seems that they don't have a telephone lines over there in NYC. The support guru was kind, easy going, and really did try to help. But there was nothing he could say that helped. Sigh.

I gave him a re-cap of my issue, the stuck print head and the broken extruder motor. He told me that the motor was probably OK and probably just jammed up with some plast. He also said that clogs happened often and that cleaning a cloged extruder was no big deal. I started feeling "supported" for the first time since I bought the product.

He had me heat up the print head and push a paper clip into it. I did that (for the 99th time that week) and same problem, plastic was slow to come through the extruder head.

The Solidoodle Review!

He told me to take off the tip of the extruder head and then soak it in acetone. He gave me instructions and then told me that it was pretty straight forward and that he was getting off the Skype line. I said that I would call back if there was a problem. I removed the yellow heat-proof tape that held on the heat sensor, and took a small wrench and started turning the tip as I held the top of the extruder since it was spinning as I turned the tip. I noticed that more than just the tip came loose. It was the tip plus the pipe that it inserted into that was coming loose. I removed that assembly a bit confused. Wasn't just the tip supposed to come off? I called back and told the tech my issue. He had me grip the pip with plyers while I turned the end cap. The extruder pipe then got all crushed, because the extruder head was on way too tightly. I told the tech the issue and held up the pipe to the Skype camera.

The Solidoodle Review!

He finally told me that the tube going to the extruder tip was damaged beyond repair and that he would be sending me a new part. Sigh. Now I had to again wait for a new part to come that 3000 mile trip from NYC.

I still think the extruder motor is damaged too. Perhaps from trying too hard to get the clog out of the printer head, or perhaps because it is just is not strong enough to do the job. Either way I feel that it is broken. I tried it again on Friday and had the same issue, it just hummed and never moved.

10/7/2012, Sunday Update: Days and days later, I'm waiting for a part and still not printing. Sigh.

10/8/2012, Monday Update: Still waiting for the part. Still not printing. So sad. So very sad.

10/9/2012, Tuesday Update: Still waiting. Went out to the mailbox, and heard that very sad sound of an empty box. Airwolf will be at the Riverside Robot Expo. Perhaps I should have gone with their printer. A friend of mine did and she's been printing for the last two months without a single jam. I suppose I am lucky that they are sending me a replacement part. They offer no official warranty.

10/10/2012, Wednesday Update: Still waiting. I can't believe what some people are writing in the comment section. I guess they figure they didn't lose their money on a broke 3D printer. Ah well. As they say, "The haters will hate and the trollers will troll."

10/11/2012, Thursday Update: Still waiting.

10/12/2012, Friday Update: Still waiting. Note to self: Air Wolf (and JPL!) will be at Riverside Robot Expo on Nov. 3rd. Need to check them out.

10/13/2012, Saturday Update: Still waiting.

10/14/2012, Sunday Update: Still waiting. Need to call Solidoodle on Monday. Sigh.

10/21/2012, Sunday Update: Emailed Solidoodle on Wednesday. They replied that the part should arrive on Friday. Friday came and went. I emailed again on Sunday morning. By Sunday afternoon I got a reply. They seemed to have forgotten / overlooked the fact that they had promised me a replacement part. They (John) said they would send out the part right away.

It has been more than three weeks since my NEW printer has stopped printing. It only has 5 printing hours on it. Really, I never intended to trash Solidoodle. If you have read any of the other 200 articles or reviews here, I've never done this sort of thing before. I'm not like a movie reviewer that just seeks to say bad things.

The truth is this: I JUST WANT TO PRINT OUT TWO ROBOT ARMS (inmoov) FOR MY LIFE-SIZE ANIMATRONIC HUMANOID ROBOT!

(Yes, I am shouting out of frustration.)

One of my friends stated that perhaps it's a good product, but that they are just growing too big and too fast, and can't keep up. Perhaps.

Another friend stated that this technology is still in its infancy and that this kind of thing is to be expected. Well, it might be.

Still one other stated that maybe all the others were fine and I had just gotten a lemon. A sour feeling does fill my mouth every time I think of that $600 printer just sitting there idle.

By the way, I just saw two different web pages with other Solidoodle customers who had also gotten lemon printers:

"...we have been waiting and working for four months for a printer that has not printed more than a couple test prints correctly..."

http://blog.richmond.edu/ti3d/2012/09/27/solidoodle-brief-review/

and

"...everytime I try to print it gets going for about 10 mins or less then stops...I think we have tried everything we can, I think I just got a lemon..."

https://groups.google.com/forum/#!msg/solidoodle/xX5gmnxWq6k/sfnOKncONB8J

I see now that I'm not the only one with Solidoodle problems. I was beginning to think that the problem was in my head. I was beginning to think that I was just a simple-minded luddite / roboticist.

One last thing for this update: please understand, I didn't start this article thinking, "I'm going to make that company's product look awful." I jreally just wanted to document the JOY of 3D printing! In fact, if Solidoodle fixes my issues and I get my arms printed, I will write all of the good things I can find about them. In fact, Solidoodle support is friendly and seems to want to help fix the issue--and that is a GREAT thing. I'll let you know when that happens. I'll let you know when the issue is fixed. I'll let you know when I have printed my robot arms. Until then, I'll keep you posted as things happen.

-Thomas

10/26/2012, Friday Update: Yesterday I got word from John at Solidoodle that they had JUST shipped me a new "hot end". (I am assuming "hot end" means the part that heats up the plastic, the part that stopped working on my printer.)

I checked the shipping service and found out that it will arrive on Wednesday, Oct. 31. Let's see, that would be 10 days from the time I was told that it would be shipped, nearly four weeks from when I was first told that I would get a new one, over a month from when I first started having problems, nearly 6 months after I had ordered the machine. You would have thought that they might send it first class, or even two day express considering all that I have been through.

I am still worried that the motor that pushes the plastic filament into the "hot end" is broken as well. The support guy told me not to worry about it. He had said that it probably was not broken, but probably had a bit of plastic jamming up the works. I hope that is all that is wrong. I hope I will be printing plastic bats and pumpkins come Halloween!

Oh drat! My coffee has gone cold. I only intended to type just a couple of lines. Sigh.

-Thomas

11/5/2012, Monday Update: On Halloween, I got the new "hot end". (The part that heats up the plastic, the part that stopped working on my printer) It arrived well packed, just as the printer had come. I unpackaged it and looked for installation instructions. There were none. I figured I would have to do another Skype session with Solidoodle for installation instructions. I really don't want to mess anything up. Of course, the Robot Expo was happening on the 3rd, so there was absolutely no time to try to get the new print extruder head installed. So there it sat (and still sits) in my "robot room" patiently waiting for me and my tools.

(Funny side note: I had planned on showcasing my Solidoodle at the robot expo printing that robot arm, but with the expo coming fast and furiously and no working Solidoodle printer in hand, I had Airwolf 3D printers come to the expo instead. You see, I run the Riverside Robot Expo every year. Anyway, instead of printing things on my own 3D printer, I watched in envy as the two Airwolf printers which they had brought to the expo worked their non-jamming magic. I also had a short conversation with the Mr. Wolf, owner of the printer company. He said that he has been reading this blog. He also said that he would take my Solidoodle printer off my hands for $600 in trade for one of his Airwolf printers. Hmmmm! His printers start at about $1700 which is why I stayed away from them in the first place. Still, the mind "wobbles" at the thought!)

So here it is November 5th. I have the new "hot end" including heating element and sensor, but I have no idea how they should be assembled. I'm not about to guess. I don't want to ruin the damn thing again. I suppose I will just have to wait until Friday morning, when I will again have time to contact Solidoodle. I have about 15 pounds of ABS that I purchased more than a month ago, just waiting for a working printer!

By the way, the motor that pushes the plastic stock into the extruder still is not working. They had said that it was probably just jammed with plastic. It does not look that way to me. It looks, sounds, and tastes (tastes? Just kidding) broken, but 3D printers and stepper motors are not my speciality. We will see if Solidoodle has an over-the-skype fix for the motor. I surely hope so. Perhaps all will pan out and I'll be printing that inmoov robot arm over the next weekend. I surely hope so.

February 15, 2013

I finally had time to replace my Solidoodle extruder, my "hot end", with the replacement parts that Solidoodle reluctantly sent to me last year. I leveled the bed and found TWO MORE PROBLEMS with my Solidoodle printer: 1. the adjustment screw is too short and the bed can't be adjusted to the proper height, and 2. the clear plastic in the print head is cracking. Sigh. Still I did manage to print a couple of small things before the head started to touch the table.

Originally I had thought of buying 10 of these printers to produce lots of robot parts, but...

-Thomas

The Solidoodle Review!

Recommendations: At this point I can only say that it would be best to save your money for a more expensive printer. Things could change, but for now I know I'm not going to buy another Solidoodle.

I'll post back to this article as things progress.

This was the Solidoodle Review Thanks for coming to Robots and Androids Dot Com!

Thomas

New! Comments

Have your say about what you just read! Leave me a comment in the box below.